Premium Industrial Cooling Towers - India's Leading Manufacturer Since 1986

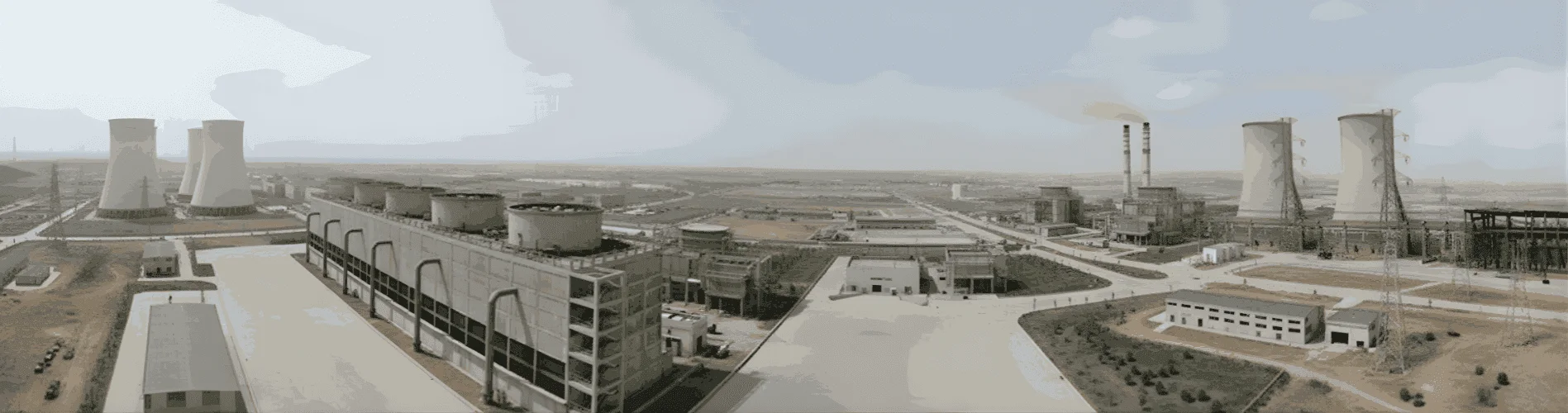

Paltech™ Cooling Towers & Equipments Limited stands as India's premier manufacturer of industrial cooling towers, serving diverse sectors including power plants, chemical processing, petrochemicals, refineries, HVAC systems, and manufacturing facilities. With over 39 years of manufacturing excellence and a track record of 9,000+ successful installations, we deliver high-performance cooling solutions engineered for reliability, efficiency, and long-term value.

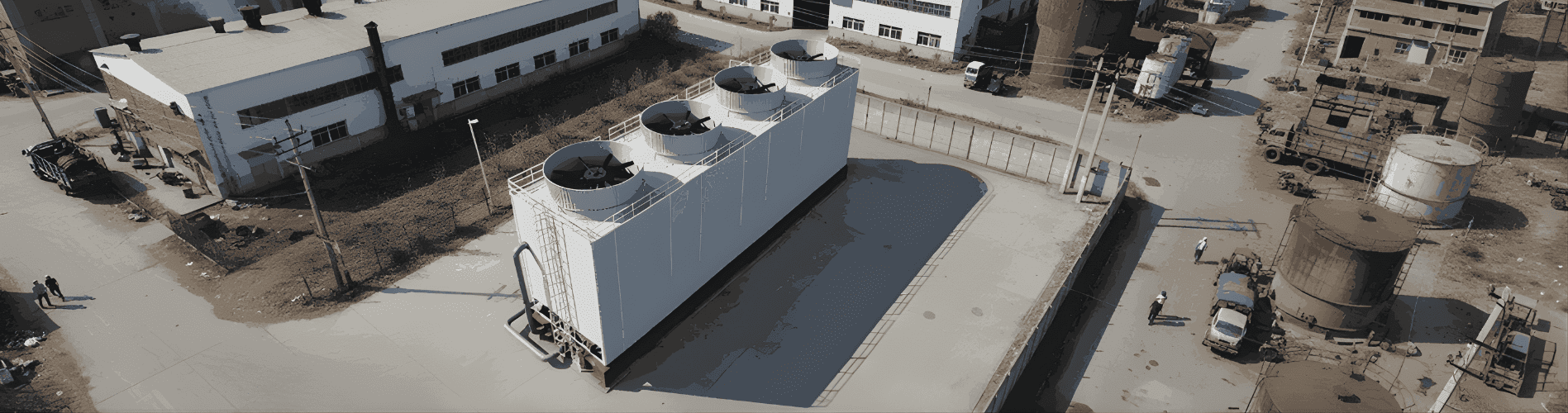

Our extensive range of cooling towers encompasses RCC concrete structures for large-scale applications, lightweight pultruded FRP systems for rapid deployment, traditional wooden towers for specific industrial needs, and versatile FRP cooling towers offering design flexibility. Each product category is manufactured using premium-grade materials, advanced engineering techniques, and rigorous quality control processes ensuring optimal thermal performance and extended service life.

Beyond manufacturing, Paltech™ provides comprehensive cooling tower services including installation, commissioning, maintenance, repair, and performance optimization. Our in-house technical team conducts detailed site surveys, offers expert consultation, and delivers customized solutions tailored to your specific cooling requirements, water chemistry, and environmental conditions.

Why Choose Paltech™ Cooling Towers?

39+ Years of Manufacturing Excellence

Established in 1986, Paltech™ has served over 11,000 clients across 46+ countries with proven expertise in cooling tower manufacturing.

ISO Certified Quality

All cooling towers manufactured in compliance with international standards including CTI, ASHRAE, and IS codes for reliable performance.

Complete After-Sales Support

Comprehensive maintenance, repair, and upgrade services ensuring optimal cooling tower performance throughout its lifecycle.

Custom Engineering Solutions

Tailored designs based on specific industrial requirements, water quality, ambient conditions, and capacity needs.

Comprehensive Cooling Tower Range for Every Industrial Application

From large-scale power plant cooling systems to compact HVAC installations, discover our complete lineup of high-performance cooling towers engineered for exceptional efficiency and durability.

RCC Concrete Cooling Towers

Cross Flow / Counter Flow

- Large-scale applications

- Up to 27,000 m³/hr capacity

- Durable concrete construction

Pultruded FRP Cooling Towers

Advanced composite technology

- Lightweight & corrosion-resistant

- Up to 4,500 m³/hr per cell

- Quick installation

Wooden/Timber Cooling Towers

Traditional yet efficient

- Proven reliability

- Cost-effective solution

- Custom maintenance support

FRP Cooling Towers

Fiber Reinforced Plastic

- Design flexibility

- Multiple shapes & colors

- Up to 1,500 TR capacity

Industrial Applications & Use Cases

Power Generation Plants

Chemical Processing Industries

Petrochemical Refineries

HVAC Systems for Commercial Buildings

Manufacturing Facilities

Data Centers & Server Rooms

Food Processing Industries

Pharmaceutical Manufacturing

Steel & Metal Processing

Textile Industries

Pulp & Paper Mills

Air Conditioning Systems

Frequently Asked Questions About Cooling Towers

What is the typical lifespan of a cooling tower?

Cooling tower lifespan varies by type and maintenance: RCC concrete towers can last 39+ years with proper maintenance, FRP cooling towers typically offer 15-25 years of service life, while wooden towers require more frequent maintenance but can operate effectively for 10-15 years. Regular maintenance, water treatment, and component replacement significantly extend operational life.

How do I choose between cross-flow and counter-flow cooling towers?

Cross-flow towers distribute water horizontally across fill media with air flowing vertically upward, ideal for lower-pressure applications. Counter-flow towers direct water downward against upward air flow, offering higher thermal efficiency and compact footprint. Selection depends on available space, capacity requirements, and energy efficiency priorities.

What maintenance is required for cooling towers?

Essential maintenance includes regular cleaning of fill media and basins, water treatment to prevent scaling and biological growth, fan and motor inspection, drift eliminator checks, and water quality monitoring. Paltech™ provides comprehensive maintenance contracts ensuring optimal performance and preventing downtime.

Can cooling towers be customized for specific applications?

Yes, Paltech™ specializes in custom-engineered cooling towers tailored to specific capacity requirements, water chemistry, ambient conditions, and space constraints. Our engineering team conducts detailed site surveys and provides customized solutions including basin design, fill selection, and structural modifications.

Ready to Optimize Your Industrial Cooling System?

Connect with our cooling tower experts for a free consultation. Get personalized recommendations, detailed specifications, and competitive pricing tailored to your industrial cooling requirements.