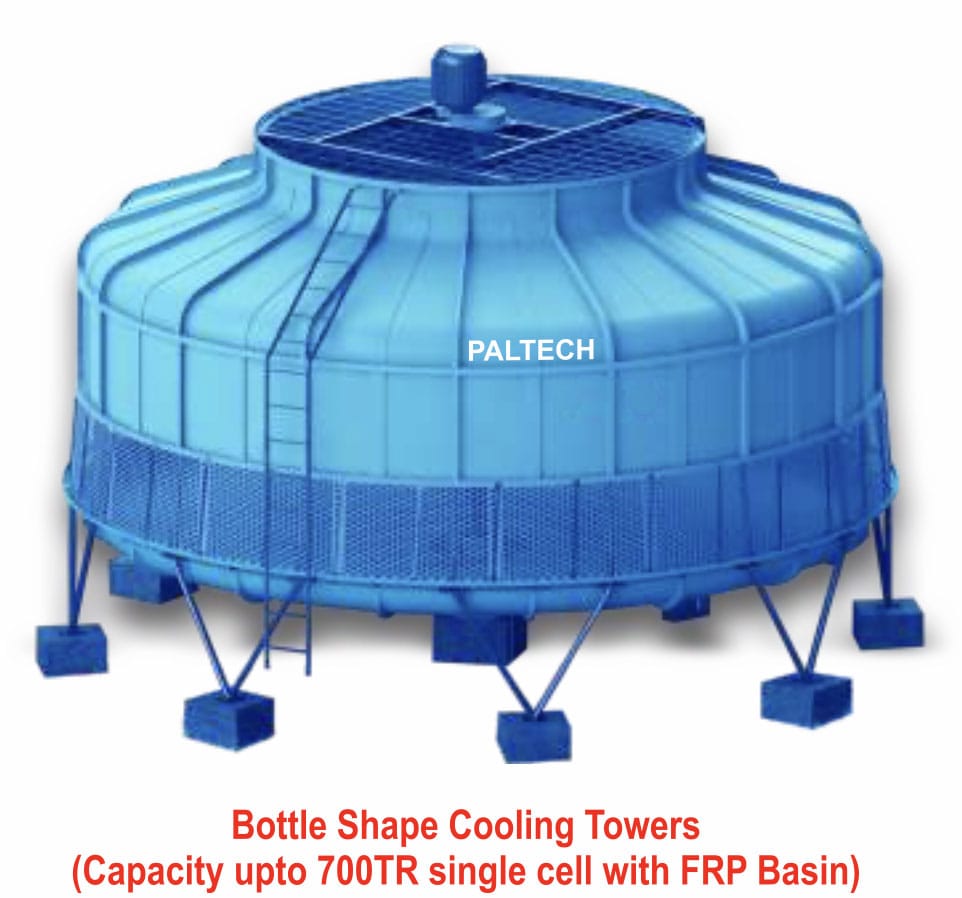

Product Description:

Our FRP cooling towers are crafted using a specially curated blend of raw materials, meticulously chosen to withstand corrosion, resist waterborne bacteria and organisms, and maintain a lightweight structure. This unique composition enables easy roof installation with specialized reinforcement, ensuring flexibility in design. The vertical induced draft counter-flow design allows for installation in any direction, providing freedom in placement.

One of the key advantages of our cooling towers is their energy efficiency. The innovative design minimizes air resistance to water, resulting in lower power consumption and reduced operational costs. Additionally, our cooling towers are available in a variety of colors, allowing them to seamlessly blend with the exterior architectural aesthetics.

Furthermore, the cooling system is equipped with a direct-driven axial fan, eliminating the issues often faced with belt and gear drives. This ensures a reliable and trouble-free operation, enhancing the overall efficiency and performance of the cooling tower.