Technical Specifications:

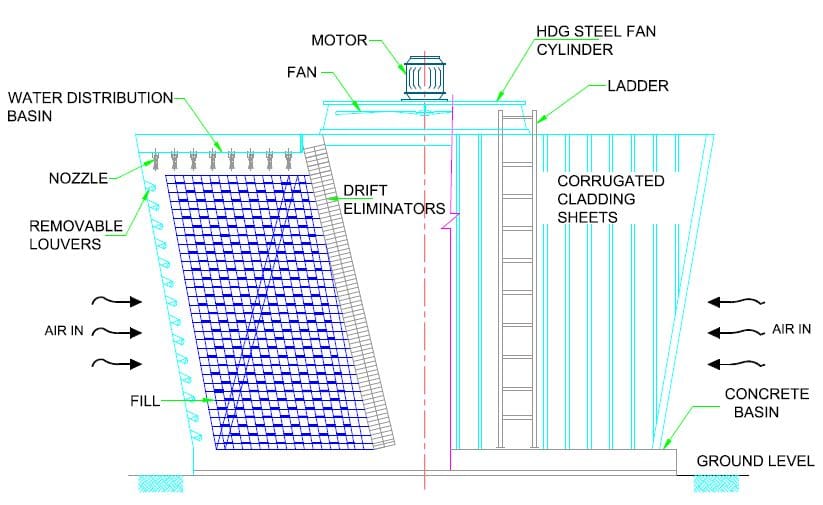

The motor integrated into the system is a special low R.P.M., totally enclosed vertical motor, flange type, with an enlarged and threaded shaft, and a sealed top. It’s designed to be totally weatherproof with IP-55 protection, making it suitable for operation in heated and humid environments.

Key Structural Components:

- Main structural components and other lightweight sections are crafted from selected preservative timber.

- All structural joints are bolted using galvanized bolts, and Stainless Steel or Phosphor Bronze hardware can be supplied at an additional cost.

- To ensure uniform water distribution, the hot water basin is equipped with a distribution box, which evenly disperses water in the hot water basin, subsequently splashing it downward through spray target nozzles.

Key Cooling Components:

- The standard cladding consists of profile corrugated sheets, with joints designed to shed water only inside the cooling tower.

- Specially designed eliminators, available in single-pass to four-pass patterns made from various materials, are provided to minimize bleed losses.

- Fill bars are designed to maximize splash surface and wetted surface, resulting in a high heat transfer rate.

- Wooden/PVC fills are supported either on wooden stringers or inside S.S. wire mesh grids, ensuring secure and permanent positioning. Various fill materials with different shapes are available to suit specific design requirements.

In this model, the fan is directly coupled with low RPM motors (vertical flange-mounted with a sealed top and enlarged threaded shaft). However, as an option, a gear-driven fan system can be provided if required for more demanding applications.